Hire Printing Experts —

Or Become One Yourself

How Our Service Works

For buyers

Our platform will take care of the quality of service and ensure your safety from unforeseen actions by the seller.

Security

For sellers

Our platform will take care of the quality of the service and ensure your safety from unforeseen actions by the seller.

"Our goal is to create a single service centre for printing companies, where any company can find a contractor to perform any job.

PressInspection.com eliminates the problem of non-payment to contractors, which is a common issue in the market. But we also ensure that the buyer receives only high-quality service."

Sergiusz Woropaj, Chief Executive Officer

More than 35 years in printing industry

"Our goal is to create a single service centre for printing companies, where any company can find a contractor to perform any job.

PressInspection.com eliminates the problem of non-payment to contractors, which is a common issue in the market. But we also ensure that the buyer receives only high-quality service."

Sergiusz Woropaj, Chief Executive Officer

More than 35 years in printing industry

The Most Popular Categories

INSPECTIONS OF PRINTING MACHINESPre-purchase Inspections of Printing Presses

QUICK CONSULTATIONSQuickly ask any expert for advice via Zoom

REPAIR & MAINTENANCERepair and maintenance with on-site service

FACTORY REPAIRSend a spare part for repair or regeneration

FREELANCERSFreelancers & Individual Contractors

RELOCATIONDismantle & Relocation of Printing Equipment

UPGRADEModernisation and upgrading of equipment for your tasks

OTHER SERVICESProduction Equipment & Peripheral Devices

How to Manage Your Current Tasks

on PressInspection.com?

Select a Service

Get Result

Insights for the Printing Industry

An objective way to solve any printing-related tasks.

Therefore, we would like to tell you about our signature service for inspecting printing equipment. It is popular among companies from all over the world because buying a used printing machine is always a risk.

An Unwilling Traveller

In its long life, a popular used printing machinery like Heidelberg CD 102 or CD 74 changes several owners. Like a traveller, it may visit different countries or even continents. We cannot know how the previous owners dismantled the machine or how it was transported. Every disassembly and subsequent reassembly of a printing machine is a serious stress on the machinery.

I remember a Heidelberg CD 74 machine where the floor reinforcement was not made all around the machine. The machine was standing correctly, but its delivery would bounce when the speed was increased. Excessive vibration led to spontaneous loosening of nuts and uneven wear of gears!

Needless to say, this error leads to increased wear and tear on any machine, regardless of the manufacturer. No matter whether it’s a Heidelberg CD 102 or even Manroland Evolution, an incorrectly installed new machine quickly becomes a wreck. The owner thinks he got an unreliable machine and should look for an excellent Heidelberg XL 105, for example, which is sure to be more reliable.

Once the decision to sell is made, the owner usually stops investing in its condition. The equipment may be on the market for six months, or even longer. All this time, the machine is still holding up thanks to the reliability of the brand and the care of the staff.

When considering offers to buy offset printing machines on the secondary market, a buyer has to understand how much this machine deserves to be bought.

And that’s where the buyer comes in…

The key point before buying a printing machine is to assess its technical condition. Obviously, it is impossible to carry out a complete diagnosis of all assemblies, units, peripherals in a few hours. This would require several days and the availability of specialised equipment. In addition, prolonged shutdown of a printing machine in a print shop is not possible for commercial reasons.

So, what’s a buyer to do if they have a couple of hours to inspect a printing machine? All he can do is check the equipment visually, or with a printed test obtained from the internet.

But the problem is 99% of the tests that a potential buyer brings with him are intended to control the parameters that lie in the field of technology (control of dot gain, SLUR/doubling, trapping, streakmarks), etc. and are not an objective factor in assessing the technical (in particular, mechanical) condition of the printing press.

These printing of these control elements will tell you a lot about the technological process in a particular printing house, about the humidity conditions, about the selected inks and the qualification of the printer, but not about the real condition of the sheet-fed system of the printing machine.

Would a potential buyer be able to identify indirect equipment problems, such as those related to the flooring of a print shop?

Everything has been invented long ago

Definitely not – the customer will see no more than 30 per cent of what our expert will notice. Whether you are buying a Heidelberg CD 102, Manroland 700 or KOMORI Lithrone, compared to the potential costs of fixing problems, our inspection will require minimal time and money. This will allow you to make an objective assessment before you buy. We start by assessing the condition of the cylinders and the sheet transfer unit. It is very important to determine the condition of the sheet feed system on machines with a sheet perfecting module like the Heidelberg SM 102-8-P. In case of hidden problems, it is very difficult and expensive to repair.

The Heidelberg service manual clearly states: the operator must turn the perfector back and forth at least once every fortnight. When trying to shift a mechanism clogged with a mixture of paper dust and oil, it can easily be broken. Many printers ignore this. And for a new owner, it can be a serious problem.

Traces of previous dismantling also matter. We have encountered situations where negligent service technicians have lost the calibrated plates that set the distance between sections. If the Heidelberg SM74 machine is dismantled into parts of 2 printing units, the Heidelberg CD74 or XL75 is disassembled unit by unit. The loss of one of the plates can lead to uneven installation and damage to the gears. The machine will soon no longer hold register.

In addition, the condition of peripheral devices should be checked. AirStar compressors on Heidelberg machines rarely live longer than ten years. A new AlсoSmart alcohol dispenser for a Heidelberg CD102 machine costs around 5K euros. Repairing a Heidelberg Axis Control can cost tens of thousands of euros. And so on. Wouldn’t it be better to pass these costs on to the seller? Just compare these expenses with the cost of our inspection and make the right decision. Your risk is inappropriate here.

Our certificate cost is an extremely small fee for you to sleep easy after buying an expensive used printing machine.

Over 35 years of experience in sheetfed offset printing, production workflows, and marketing.

He began his career in print shops and later worked with leading suppliers and service partners in the industry. He contributed to market development and customer support for Heidelberger Druckmaschinen (from 1997), and later collaborated with Boettcher Systems (from 2010) and ROEPA (from 2011). He spent over 12 years with Heidelberger Druckmaschinen Osteuropa Vertriebs-GmbH, first as a regional representative and then as a branch manager. Since 2011, he has been a trading partner of H. Roesinger & Partner (France) and has completed professional training at the Heidelberg Print Media Academy.

Today, together with an international team of specialists, he is helping reshape the printing-services market through the PressInspection marketplace — making expert support more stable and predictable for print businesses, while enabling professionals from different countries to reach new clients in a clear, trusted B2B environment.

Professional Inspection Оf Printing Machinery

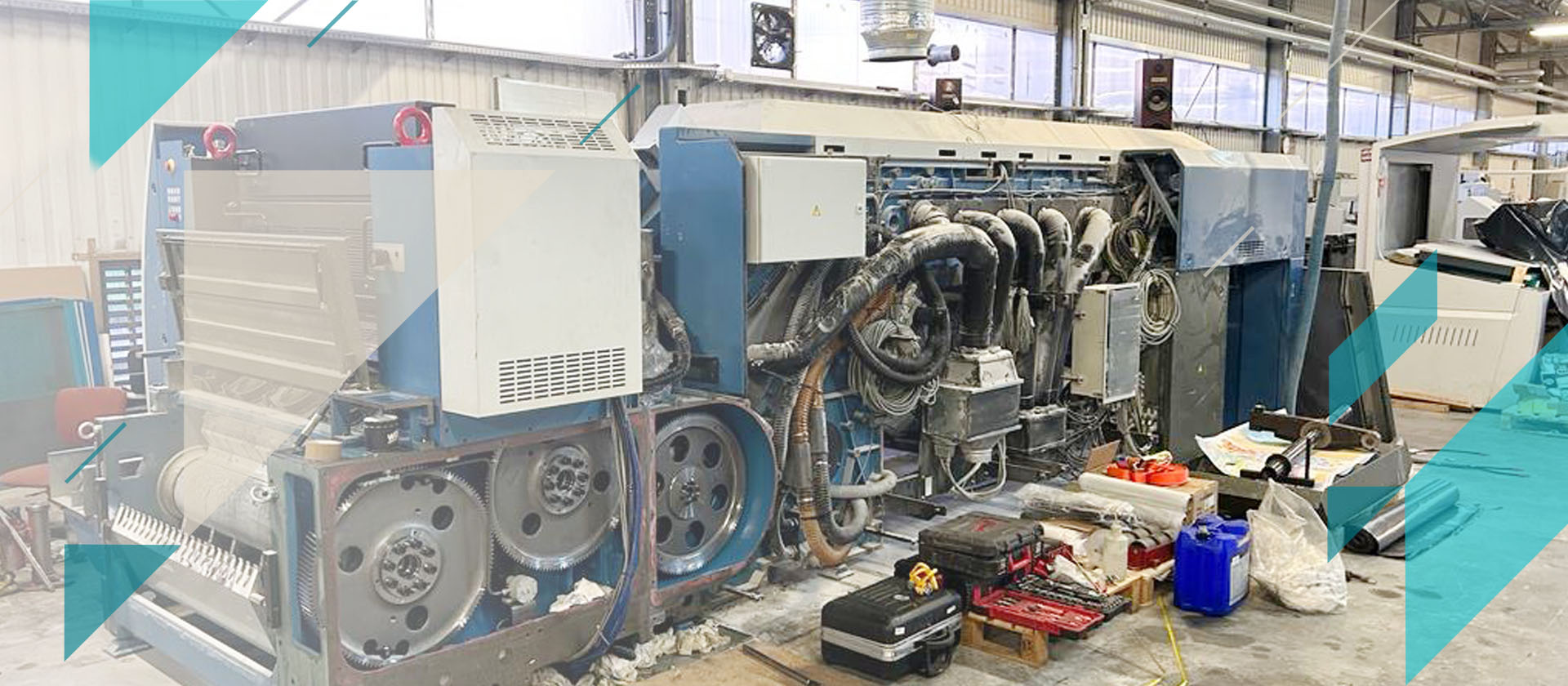

You want to buy any machine for printing industry and have already found a suitable offer from a dealer. However, you don’t know what has happened to the machine in the past and what is hiding inside behind the beautiful pictures. Look at the pictures we took these pictures in different locations over a period of several months. All these, and many other problems after payment become the buyer’s headache.

The seller will definitely show you what you want to see. However, when you pay the money and the machine arrives at your print shop, there may be many troubles you didn’t even realise were there. Cinderella’s beautiful carriage turns into an unmoving pumpkin, and now you’ll have to think about where to get the money for repairs.

Book our independent inspection of the used machine before you pay for it. Our inspection reduces the risk of costly repairs in the future.