Sergiusz Woropaj, Author at PressInspection.com | Page 2 of 4

Our story today is about a sheetfed offset printing machine that was not destined to live a long and happy life. It was produced for a very short period of time – from 1984 to 1994, but it is notable for the fact that it was an attempt by Heidelberg to gain a foothold in a market that was still in its infancy at that time – the market of one or two-colour accent printing and to compete with cheap duplicators.

It can be considered the progenitor of modern digital printing solutions, which is the latest generation has a name Heidelberg Versafire. Of course, to reach today’s positions, Heidelberg still has a very long way to go with its Quickmaster 46-4 DI experiments, later with the Kodak NexPress and already in the 2010s with the Ricoh Digimaster, but all these machine series also have their roots in offset printing.

Where did it all start?

You’ve probably figured it out by now. We’re talking about the Heidelberg T-Offset series, small 28x39cm duplicators capable of running at speeds of up to 10 thousand sheets per hour.

Until the early 80s, Heidelberg already had experience in the small-print niche. But the only printing machine GTO was too little automated and rather bulky for the office, and gradually new unexpected players from the American and Japanese market – Hamada, Ryobi, AB Dick – began to appear in the niche of accent printing. It was in the early 80’s that copy parlours, which specialised in printing cheques, forms, tickets. They were simple, easy to maintain and not requiring special conditions, flourished.

The advantage of such copy parlours was that it did not require huge premises and high-precision equipment. It could be opened close to the consumer – even in a neighbouring house or on a busy street. A bank or a large office could have its own printing area for documentation.

Of course, Heidelberg was counting on the success of the new machine. Demonstration buses were sent to customers all over the world, in which operators showed them the whole printing process – from plate making to trimming.

A versatile machine for short runs

The idea of cheap and quick print production was actively taken up by manufacturers of plates for printing. Materials could be lit in a small-format copy frame and developed in a compact processor. This made it easy to take a photograph of the original, which did not even need to be rasterised, and immediately produce a plate for it.

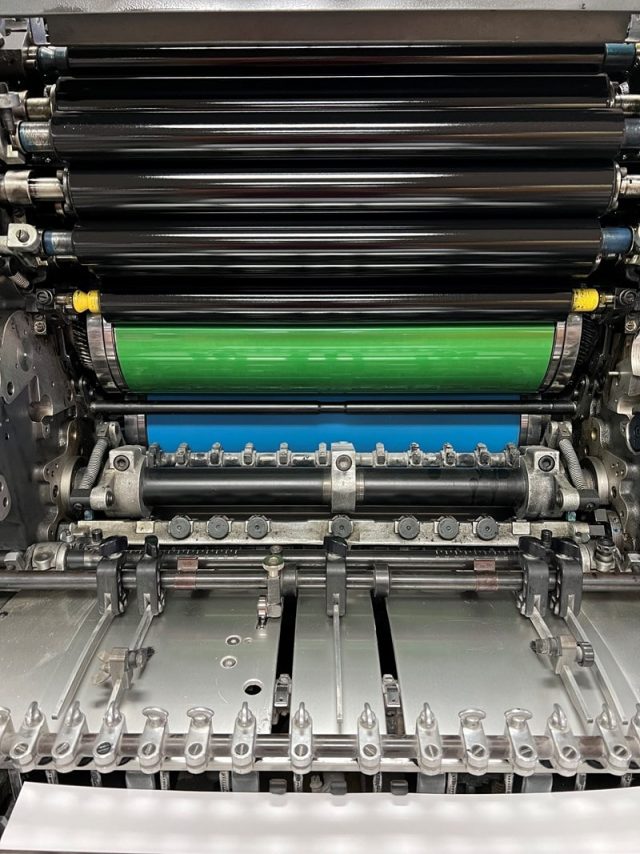

Ink unit

The requirements for the ink machine of such a machine are also different from those of large format machines. There are no large areas to seal. All it’s needed from the machine is only required to roll out the printing ink well and evenly.

In the Heidelberg T-offset, a completely unusual ink system is used. The ink was rolled onto the plate by… just one large-diameter roller – its size was half the diameter of the plate cylinder.

The scheme of the ink unit meant that the paint flow was divided into two streams. Only three rollers fed all the ink from the ductor cylinder to the knurling roller. At the same time, the other seven rollers simply spread and levelled the knurled paint over the surface of the large knurling roller.

Dampening unit

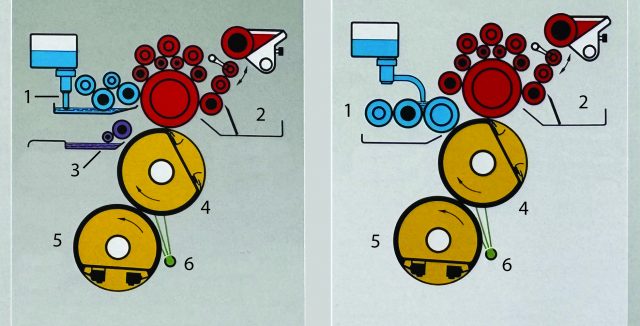

Depending on the printing plate used, the machine could have one of two types of dampening units.

1. Combined unit – dampening was not applied to the plate, but to the large rubber plate roller. On its surface was created a film ‘ink – water’ in the required proportion, which was applied to the foil plate. The design of such a printing machine included several other rollers, which you will not find in modern machines. These performed the function of etching the foil plate.

2. Conventional separate dampening unit with cloth rollers that formed the film ‘ink – water’ on the plate cylinder.

The construction of the printing machine

Despite its appearance of lightness, the machine was precise and designed for long-term operation.

The plate and printing cylinders were cast from steel alloy, while the offset blanket cylinder was hollow inside and made of aluminium.

The cylinders had slip rings, which increased the stability of the machine and achieved really high dot quality. But most importantly, the cylinders were mounted on tapered needle bearings without clearance, as in big multi-colour presses. The construction of these quite expensive bearings are highly accurate and almost wear-free.

Steel grippers with replaceable polyurethane pads could be repaired and worn ones easily replaced.

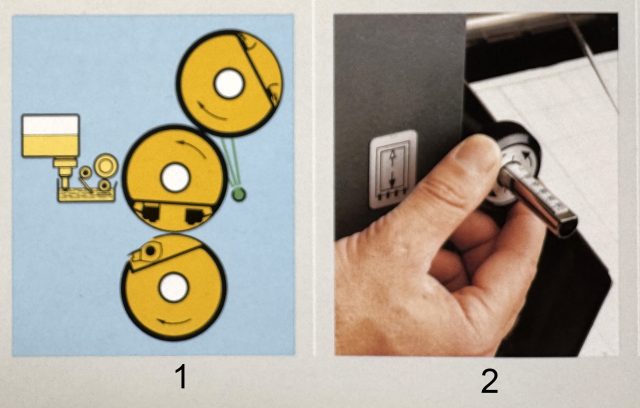

The offset cylinder was fitted with a quick washing device using a special roller with low material density. It is shown in the figure below (1). Its rubber was only designed to use environmentally friendly materials. When the printer tried to wash the machine with cheap paraffin, the roller would change its structure and swell. It was quite expensive to replace the roller, and over time printers reverted to flushing the offset web with a regular rag…

Feeder and delivery

The sheet feeding was carried out by the narrow side.

There was no side stop in the machine. The operator could simply move the foot by adjusting the side bar (2). The precise side feed adjustment required for full-colour printing was out of the question – for one or two-colour printing on bills or envelops, such an alignment was quite sufficient. It was assumed that the sheets of paper would be neatly trimmed and the machine would not print jobs requiring a second run of sheets.

There was no side stop in the machine. The operator could simply move the foot by adjusting the side bar (2). The precise side feed adjustment required for full-colour printing was out of the question – for one or two-colour printing on bills or envelops, such an alignment was quite sufficient. It was assumed that the sheets of paper would be neatly trimmed and the machine would not print jobs requiring a second run of sheets.

There were two versions, differing in the design of the delivery. They differed in that the TOK had a tray stacker, while the TOM had a table that could be dropped to the floor.

Accessories

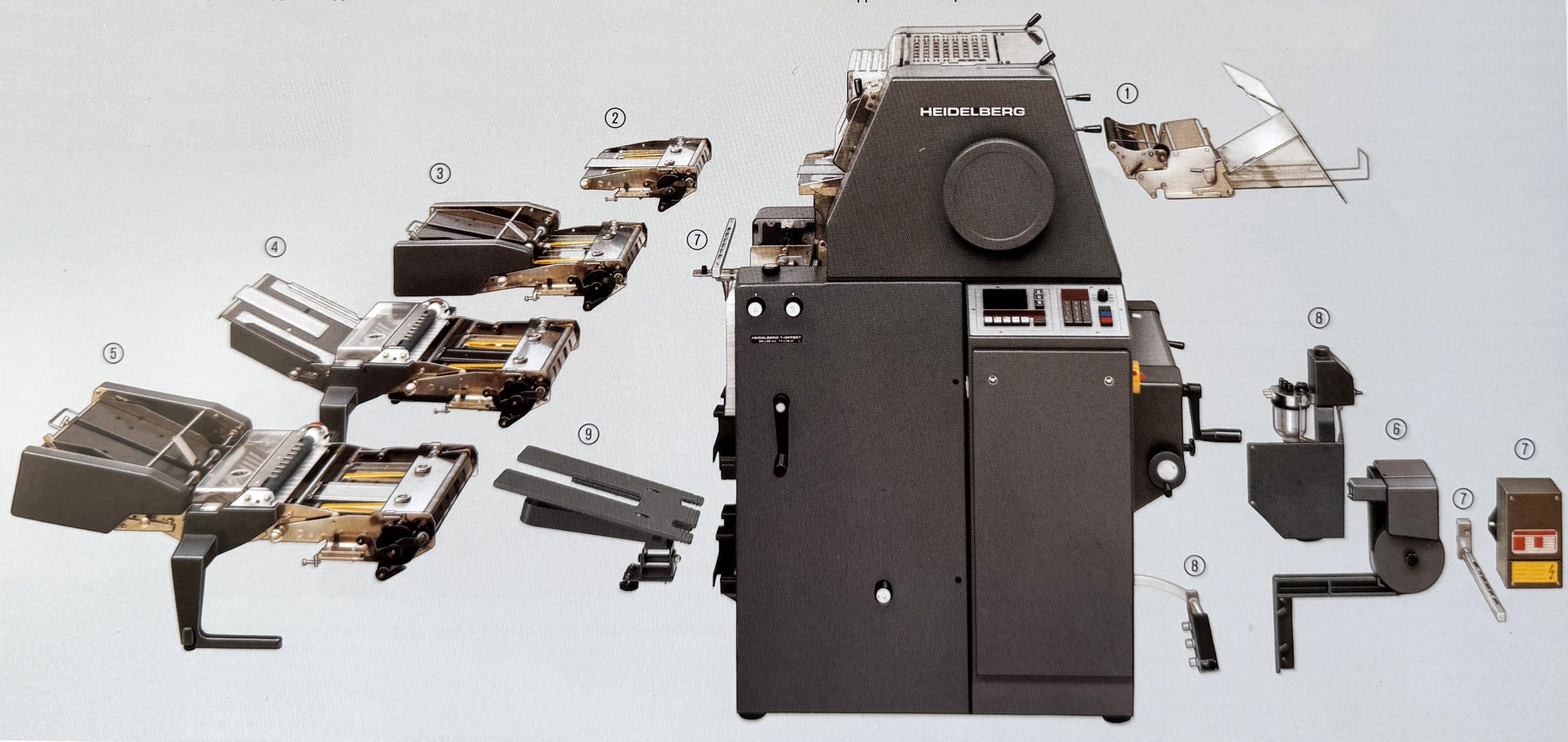

This is the most interesting part of our review. The T-Offset series was conceived as the basis for copy shops, whose equipment can quickly fulfil any job. That is why an impressive list of optional equipment has been prepared for the machines.

That’s not all. The printing machine could be connected to a sorter with 60 or 120 shelves. In total, up to 10 towers with a total of up to 600 shelves could be connected in line to the machine! You have to agree that in this configuration the printing line already resembles modern digital printing machines with sorters.

But the most incredible piece of optional equipment on the Heidelberg T-Offset machine was the online plate exposing device manufactured by Bacher. Using a feed tray, a paper original was inserted into the camera. It was photographed there, exposed on a special silver-containing plate material, developed and fed into the machine.

Advantages and disadvantages

Heidelberg managed to create the best in its class offset printing duplicator, which was to be a worthy replacement for the famous Tiegel letterpress machine. It was as automated as possible, which for the mid-1980s looked like an emerging printing standard.

The ink unit was quick to produce quality prints in as little as 50 sheets. The length of the circumference of the large knurling roller exceeded the length of the surface to be printed, and templating was completely eliminated. The small ink capacity allowed quick adjustment for new work. But operation showed the serious disadvantages of having a single knurling colour roller. The slightest damage to the roller, which could be caused by a foreign object, resulted in a printing defect. The roller was very expensive and difficult to replace.

Despite the presence of an impressive list of peripherals, the plate setting itself was not fully automated. The machine included both a quick-clamping bar, which had to be closed with a special tool, and a bar with hooks. The machine could automatically insert and clamp only the non-perforated plate. The full automatic plate changing system for all kinds of plate material could not be installed on the machine.

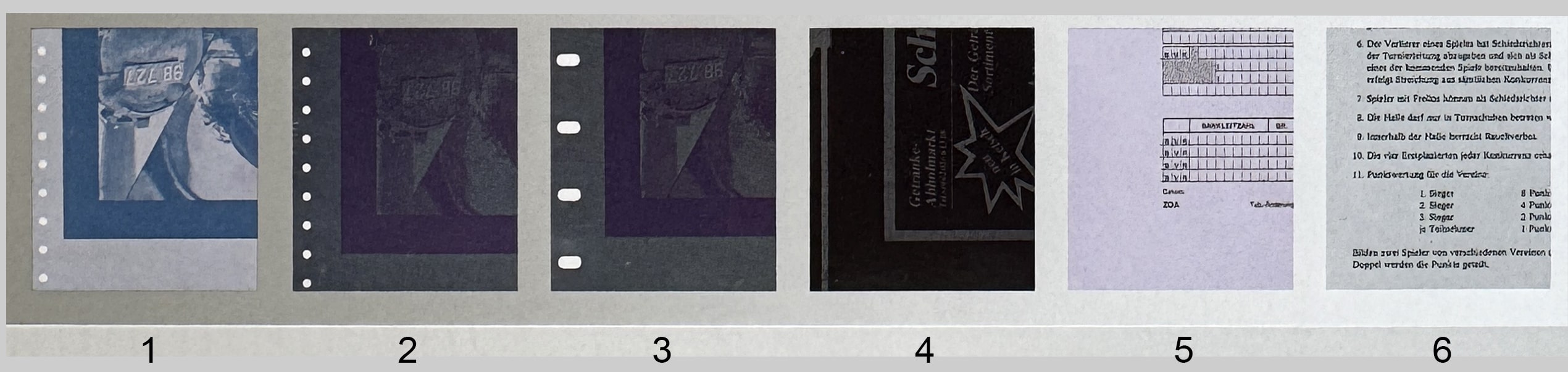

Plates that were common in the accidental printing

1. Aluminium printing plate with straight edge or perforated edge. Perforation pitch 12.5 mm, perforation diameter 4.5 mm. The standard was widely distributed and was called ‘International’. Plates are even today the most common form material in offset printing.

2. Aluminium printing plate with perforated edge. Pitch of perforation is 12,7 mm. Perforation diameter – 4 mm. This perforation standard had the name ‘Pinbar’. Exposure method – photographic camera followed by etching. Circulation resistance – up to 10 thousand impressions.

3. Aluminium printing plate with perforated edge. Perforation pitch 29.6 mm. Perforation width – 5.5 mm. Exposure method – photo camera with subsequent etching. Circulation resistance – up to 10 thousand impressions.

4. Polyester printing plate based on silver-containing copying layer. Exposed by direct photographic process. It was possible to use with perforated edge. Circulation resistance – about 20 thousand impressions.

5. Paper-based printing plate with non-perforated edge. Manufactured by laser printer or copier, but requiring etching with zinc oxide. Print resistance – up to 7-10 thousand impressions.

6. Paper-based printing plate with non-perforated edge. Printability – up to 3,000 impressions. Produced on a copier or laser printer.

Conclusions

But most importantly, the machine was not at all adapted for printing multi-colour raster works, where exact colour matching was required. It was conceived as a complement to a multi-colour machine. Thus, the possibilities of the Heidelberg T-Offset were still very limited.

The format of the machine was the same as the former letterpress Tiegel machines – 28×39 cm. But soon everyone found out that it was inconvenient and did not match any other printing machine. New machine could not work in tandem with the Heidelberg GTO’s 34×46 cm and 36×52 cm formats.

Obviously, Heidelberg relied on the T-Offset series of printing machines, but the huge amount of peripheral equipment produced, such as various feeders and sorters, made the machine unreasonably expensive. In addition, the solution turned out to be inconvenient due to the ill-conceived system of ink rolling and non-automated system of plates setting.

After ten years of production, the series was discontinued in 1994. But Heidelberg did not give up producing equipment for the excitation niche, and the T-Offset model was replaced by another machine, the Quickmaster 46, where the engineers did a lot of work on the mistakes.

Used photos from public sources and materials of Heidelberger Druckmaschinen AG

With the advent of relatively inexpensive plate exposure devices in the mid-2000s, the popularity of Computer-to-Print machines, where each print unit was equipped with a separate laser head, began to decline.

It should be recalled that such machines had been developed by both Heidelberg and a number of other equipment manufacturers since the late 80s with the aim of stabilising quality and reducing the impact of dampening on the printing process.

With the plate making process stabilised and easy to calibrate, it was time to get to grips with the ink machine.

How printing machines have changed over the last 30 years

My thesis at the University of Printing was to investigate the effect of the inertia of an inking unit of classic printing machine with different ink capacities when increasing and decreasing the ink. The printing machine should have not be have any characteristic curves and any electronic interference in the printing process. During the print run we increased the ink supply and measured with a densitometer how many sheets the machine would reach a stability. In general, after the change in ink adjustment, the Adast Dominant from the late 80s was achieving stability in 150 sheets. The Planeta Varimat – in 300 sheets, and the 1995 GTO 52 – in 80 sheets.

All this points to the imperfection of the colour machines of those years. That’s why all machine manufacturers were actively engaged in reducing changeover costs, namely reducing the number of sheets rejected during changeover.

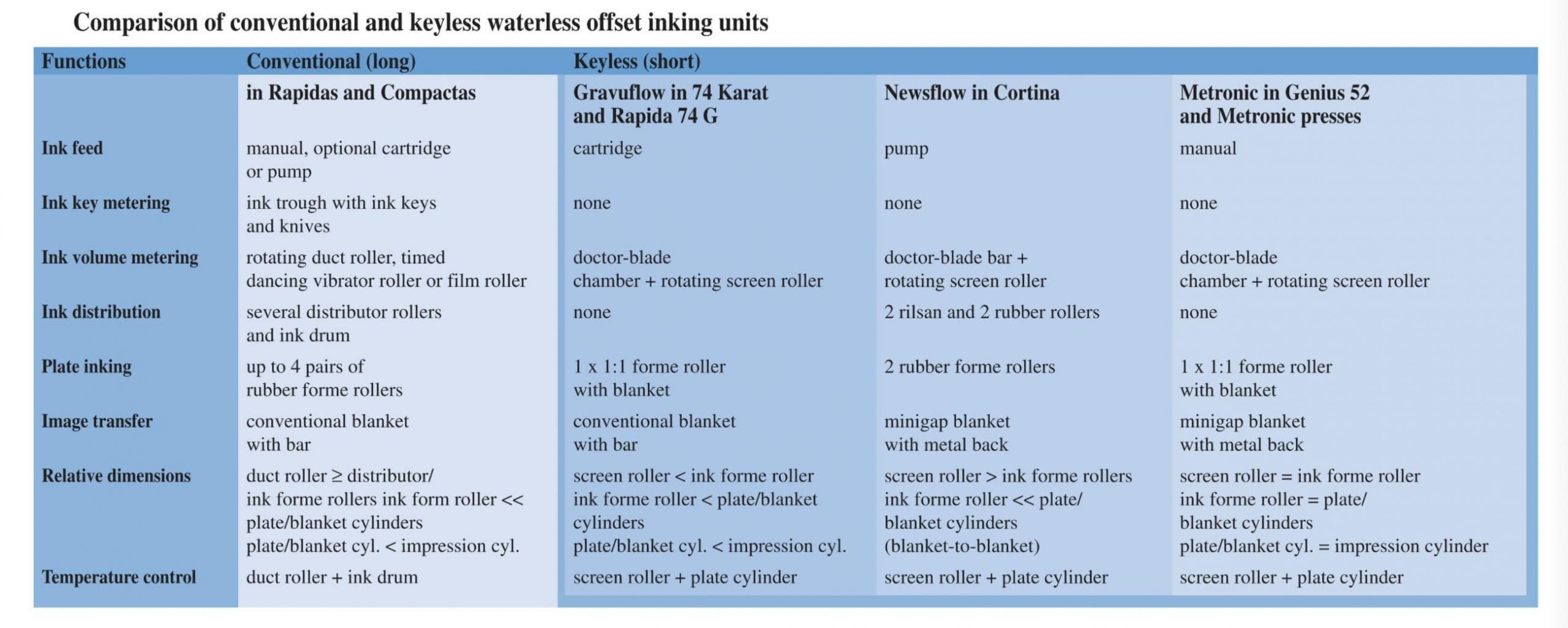

Both technologies – KBA Gravuflow and Heidelberg Anicolor – were 2000s attempts to improve on traditional offset for small runs, but the working principle was different.

While Heidelberg worked with Presstek to develop machines each with its own CTP, Koenig & Bauer took a different route. They decided to reduce the number of sheets per changeover by rethinking the design of the ink unit of the printing machine in principle.

KBA Gravuflow: design and history

KBA Gravuflow is a waterless offset technology developed by Koenig & Bauer (KBA) in the 1990s. Unlike traditional offset, it used an anilox roll to precisely dispense ink, which ensured high colour stability and eliminated the need for a dampening solution.

KBA Gravuflow is a waterless offset technology developed by Koenig & Bauer (KBA) in the 1990s. Unlike traditional offset, it used an anilox roll to precisely dispense ink, which ensured high colour stability and eliminated the need for a dampening solution.

Gravuflow was first introduced at DRUPA 2000 in the KBA Rapida 74 G machine. Four years later, at DRUPA 2004, the compact KBA Genius 52 machine was shown, also using Gravuflow.

Unfortunately, after a quarter of a century, there is little information about this technology. But I have in my possession a KBA Process magazine from 2005, when dry offset technology was in its heyday.

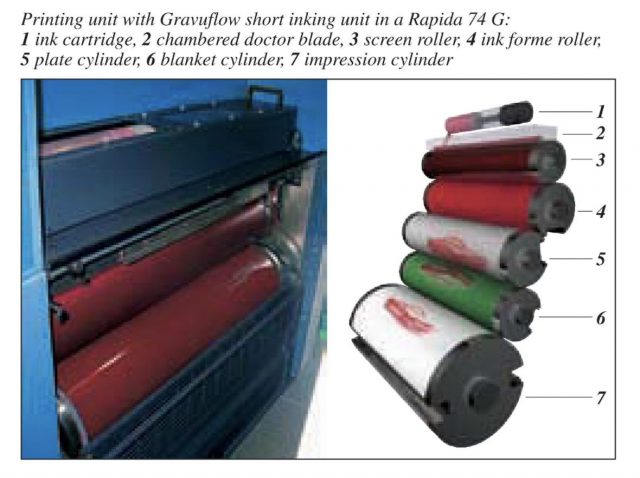

How does the Gravuflow press work?

The main difference between the KBA Gravuflow and conventional offset is the absence of zonal ink adjustment. In conventional offset, the ink is fed through zone screws that adjust the layer thickness manually. In Gravuflow, this process is eliminated and that is why more precise.

The main design elements are:

- Anilox roller (engraved roller)

- It has a surface with microcells that hold the colour.

- The number and depth of the cells determine the thickness of the paint layer.

- Allows the delivery of a precisely metered amount of ink to the printing plate.

- Chamber doctor blade system

- Excess ink is removed from the anilox roll by a special doctor, leaving only the exact amount of ink in the cells.

- Printing plate

- Waterless offset plates are used, similar to those produced by Toray.

- Unlike conventional offset, it does not require adjustment of the moisturising solution supply.

- Offset cylinder and printing cylinder

- Classic offset scheme: ink is transferred from the plate to the offset cylinder and then to the material to be printed.

Evolution of Gravuflow on different machines

KBA Rapida 74 G (2000) – the classic Gravuflow

Features:

- Full-format offset machine ( 50×70 cm format ).

- Used an anilox roller for ink delivery as in gravure printing.

- Supported fast plate change.

- Designed for medium runs (from 500 copies) where standard offset was inefficient.

Themain problem was the high cost of waterless plates and the difficulty of handling high runs.

KBA Karat 74 (1995-2002) – a joint project with Scitex

Features:

- One of the first DI (Direct Imaging) machines where plate exposure took place right inside the machine.

- Used Gravuflow for precise ink metering.

- It was oriented to digital offset, but did not become widespread.

Main disadvantages were high price and difficult maintenance.

KBA Genius 52 (2004) was the latest evolution of the Gravuflow

Features:

- Compact offset machine for 52×36 cm format .

- Completely waterless printing (analogue to Presstek DI technology).

- Used Gravuflow with anilox rollers on each colour machine.

- It was characterised by ultra-short set-up – only 5-10 sheets of waste.

- It supported printing on non-standard materials (plastic, cardboard, metal).

Genius 52 did not become a standard due to the high price of equipment and consumables. In addition, competition from digital machines (HP Indigo, Xerox iGen) increased in the late 2000s.

Why did Gravuflow disappear from the market?

Despite the technical advantages, the technology did not become widespread for a number of reasons:

- Thehigh cost of plates and inks – waterless plates were more expensive than conventional plates, and the inks required special conditions.

- Difficulty working on large print runs – waterless offset overheats and is unstable for long printruns.

- Development of digital printing – HP Indigo, Xerox iGen machines made waterless offset less popular.

- Competition with Anicolor – Heidelberg Anicolor, introduced in 2006, proved easier and more efficient for short runs.

Today, Gravuflow is only found on used KBA Genius and Karat machines, but active use of this technology stopped after the 2010s.

Heidelberg Anicolor: design and history

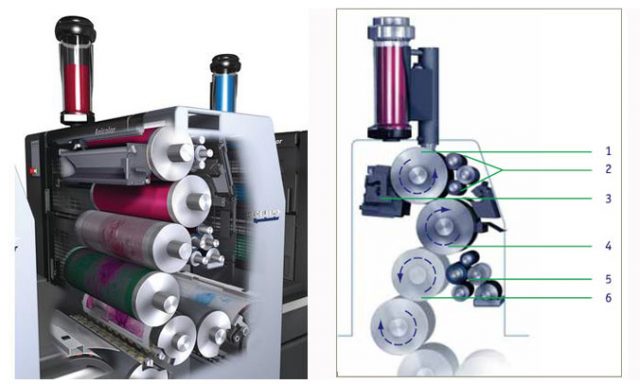

Anicolor technology was developed by the German company Heidelberg and introduced in 2006. This curious offset printing technology appeared on Speedmaster SM52 machines with a short inkjet. It combined the advantages of offset and digital printing, offering high quality and fast changeovers.

History of the Heidelberg Anicolor

Prior to Anicolor, Heidelberg had developed traditional offset machines, but these had the serious disadvantage of high set-up times and materials, especially for small runs. The company was looking for ways to reduce the cost of switching from one order to another, as the market in the early 2000s began to demand shorter runs, faster turnaround times and minimising waste.

Anicolor’s main objective was to:

- To reduce makeready times to less than 10 sheets (instead of 100+ in traditional offset).

- To eliminate the use of complex zonal ink supply adjustments.

- To achieve high colour consistency and print accuracy with minimal human error.

The use of a single rasterised anilox cylinder in each ink unit solved many technological problems simultaneously. In 2007, in the Vetter beer hall in Heidelberg, we crossed paths with Anton Dyuzhenkov, the owner of the printing house ‘Colour Formula’. It was the first in the CIS countries to purchase a four-colour machine with Anicolor. Anton spoke enthusiastically about the test results and claimed that the machine was completely devoid of the disadvantages of the classic printing process. He came to do tests on the new machine before the purchase and prepared an incredibly complex test plate, which a printing machine with an ordinary colour machine would never have coped with.

Results of printing test

Firstly, the machine was completely devoid of templating problems. Anton placed on the sheet on one side large sealing surfaces with small white space elements inside. And on the other side – a small control element on a blank sheet, which had to have a higher optical density.

Secondly, the machine has no local adjustment screws for the ink zones. All surfaces of an Anicolor printed sheet have the same optical density. It is possible to change the overall adjustment of the ink supply by changing the viscosity of the ink by increasing or decreasing the temperature of the rollers, and this within a range of 10 per cent. Thus we can say that the printing process is strictly standardised.

Thirdly, plate output is handled by a conventional CTP device, which only needs to be calibrated once. After that, the human influence on the printing quality ends.

Fourth, the first generations of the machine were only capable of CMYK printing. After 2008, mixed ink printing was introduced, and after a few more years Anicolor appeared on the Heidelberg XL75 machine.

Competitors before the introduction of Anicolor

Before the advent of this technology, Heidelberg’s main competitors in the short run segment were:

- Traditional offset machines (Komori, KBA, Ryobi, Manroland)

- Characterised by high colour stability and low production costs for large runs, but inefficient for small orders due to long set-up times.

- Digital printing machines (HP Indigo, Xerox iGen, Canon, Konica Minolta)

- Allowed to print from one copy without set-up, but were inferior to offset in quality, cost on medium runs and variety of materials to be printed.

Disadvantages of competitors to Anicolor

- Conventional offset required significant setup and colour correction costs.

- Digital printing offered less choice of papers, inks were less durable and the cost of production was higher for medium runs (500-2000 copies).

- Hybrid systems (such as Heidelberg Quickmaster 46-4 DI, Speedmaster SM74 DI, Ryobi 3304 DI) with laser units in each unit, although they reduced set-up time, were still inferior to Anicolor in terms of speed and economy, while Presstek polyester plates were also inferior in terms of quality.

Advantages of Anicolor

- Minimal makeready – 6-10 sheets of paper per makeready.

- Automatic ink feed adjustment – no complicated zoneadjustments.

- High colour stability – perfect colour from the first print run. Offset printing could now be free of human error, calibrated and standardised.

- Cost-effective – the cost of printing is similar to traditional offset for medium runs. But Anisolor is able to quickly print short runs of 50 or 100 sheets, which would be unprofitable for a conventional offset printer.

- Compatible with classic offset papers – without the limitations of digital printing.The SM52 sheet feeder is the sheet feeder of a conventional press, capable of printing up to 15 thousand sheets per hour.

Key differences between KBA Gravuflow and Heidelberg Anicolor

| KBA Gravuflow | Heidelberg Anicolor | |

| Type of Printing | Waterless Offset | Water Offset with short inking unit |

| Working Principle | Uses an anilox roller and an ink metering system through engraved cells | Uses an anilox roller but without zone control of the ink supply. |

| Colour stability | High, as there is no dampening solution | High, due to even and uniform colour distribution |

| Set-up | Low set-up costs | Low set-up costs (6–10 sheets) |

| Disadvantages | Requires special Toray waterless offset plates and special operating conditions.

Inks are more than twice as expensive as conventional inks and are very rarely available |

More expensive than traditional offset, but cheaper than digital technology for medium runs |

Anicolor was a major step forward, occupying a niche between offset and digital, allowing printers to handle short to medium runs without sacrificing quality and at a lower cost.

It is worth noting that the technology still exists today. The Heidelberg XL75 Anicolor machine was still on display at DRUPA 2025.

The vast majority of people involved with offset printing are well aware of how the image is formed. We have talked about it in our articles too. However, the main problem with offset printing has always been the difficult-to-control application of the dampening solution to the plate. That’s why manufacturers of printing machines have always thought about how to improve the process.

The first attempts to get rid of dampening in offset printing date back to the mid-60s. This is how a trend called Waterless Offset Printing came into being.

3M developed the first waterless offset plates as an alternative to traditional offset to avoid problems with dampening solution and thus improve print quality. The main reasons why engineers were looking for a waterless solution were:

1. Problems with the water-colour balance

In classic offset, the wetting solution must be precisely dosed, otherwise blurred areas, ink emulsification and colour instability occur. The most common at the time were dampening units were equipped with plush rollers. It was exceptionally difficult to obtain a stable film.

A small change in temperature or in the composition of the moisturising solution had a dramatic effect on the print. To combat the effects of temperature, some ink temperature control (ITC) devices appeared in printing machines.

2. The desire to improve print quality

Without water, the ink is more evenly layered, providing more contrast, saturation and detail.

This is especially important for highly artistic and accurate colour reproduction (e.g. for multi-colour works).

3 Environmental and economic benefits

The elimination of chemical components (isopropyl alcohol and other substances in the moisturising solution additives) reduces harmful emissions into the atmosphere.

The quicker the print is ready, the less paper is used for finishing.

Who pioneered waterless offset?

The first waterless offset printing plate was invented by the American company 3M in 1968. It was a special plate with silicone surface that repelled ink from the non-imprinting elements. After exposing the plate, the silicone was washed off the printing elements and remained on the whitespace elements. However, the technology did not become widespread until the 1970s, when the Japanese company TORAY Industries refined the idea and began commercial production of waterless offset plates. These became the standard for waterless printing and are still in use today.

The role of key companies in the development of the technology

3M (USA) – pioneers of waterless plates

In 1968 the company developed the first waterless plate. Several problems were encountered both in the development of suitable inks for this process and more importantly, in the durability of the driography plate. After several years of research and development and many millions of dollars invested, 3M chose not to pursue further development of the product. The technology was not a commercial success as it required expensive special inks.

TORAY Industries (Japan) – the first mass producer of waterless plates

In 1972, Toray Industries, a large Japanese company specializing in synthetic materials development and manufacturing, purchased the patents for the waterless products from 3M. Related patents were also purchased from the Scott Paper Co., who were working on a similar project.

Toray’s experience in working with synthetic materials and advanced polymer compounds allowed them to improve on the original product design. After some five years of research and development, the Toray Waterless Plate was introduced at DRUPA in 1977 and became the industry standard.

Presstek (USA) – digital waterless printing

In 1987, the company developed a waterless offset analogue solution using laser exposition. Their DI (Direct Imaging) technology allowed for printing without lay-up, which made waterless printing convenient for small runs.

Heidelberg (Germany) – introducing waterless offset to the industry

In the 1990, the company started to produce waterless printing machines called GTO-DI and later – Quickmaster 46-4 DI (developed together with Presstek).

Heidelberg found promise in the new Presstek’s technology and offered new plates for its GTO-DI machine and later unwindable polyester webs with a laser burned silicone layer, which were used in the Quickmaster 46-4 DI.

However, Heidelberg later abandoned purely waterless technology in favour of Anicolor, which used the advantages of traditional offset but with minimised moisture problems. Presstek continued to produce plates for the Ryobi 3304 DI and for the in-house developed press even when Heidelberg became disillusioned with the technology and discontinued their machine.

Koenig & Bauer (KBA) (Germany) – an attempt to create an industrial waterless offset press for printing multi-colour work

In 2004, KBA (Koenig & Bauer) showed at DRUPA the KBA Rapida 74 printing machine with a Gravuflow technology without the usual ink rollers. This was an attempt to create an alternative to standard offset using waterless technology. It used an engraved anilox roller that fed a strictly metered amount of ink. However, the technology did not become widespread due to the high cost of materials and difficulties in printing large runs.

Rapida machines, especially the Rapida 74-6+L versions, are still on the market today and stand out for their very low price. When buying such a machine, some used equipment dealers avoid mentioning that this machine does not have the classic rubber rollers and try to attract the buyer with the low price of the machine. If a buyer accidentally purchases such a machine out of ignorance, he will face serious difficulties.

A little later came printing machines such as the Genius 52 and Karat 52.

Why did many companies experiment with waterless offset in the 90s-2000s?

Problems with conventional offset

Conventional offset requires precise control of dampening – even small changes in temperature or solution chemistry can cause print instability.

Set-up times and paper waste were significant, especially for short runs.

Popularity of waterless technology

Waterless offset offered better colour control as there was no wetting solution to dilute the ink.

Reduced environmental pollution as no chemicals were used to regulate the moisturising solution.

The Japanese company Toray developed waterless offset plates and many printing machine manufacturers (Komori, KBA, Heidelberg) began adapting them to their systems.

Limitations of waterless offset

- Expensive consumables – waterless plates were more expensive than standard plates.

- Temperature sensitivity – the machine could produce unstable results when heated.

- Non-universality – it was impossible to print on all types of paper, especially on absorbent materials.

Why didn’t waterless offset become the standard?

Despite the interest in the technology, traditional offset remained more versatile and digital printing was getting better. Therefore, waterless offset never replaced classic methods, and technologies such as Heidelberg Anicolor became more viable alternatives.

While waterless offset has a number of advantages, it also has serious disadvantages:

- High plate price – waterless offsetplates are much more expensive than conventional plates. Requires special equipment to develop them.

- Sensitivity to temperature – printing is unstable even with a slight increase in temperature inside the machine.

- Limited choice of inks – requires a special low tack ink capable of being fed through an anilox rasterised roll.

- Non-universality – you can’t print on all types of paper.

Therefore, the technology has not replaced traditional offset, but has found limited use in premium printing, document security and low-volume offset printing.

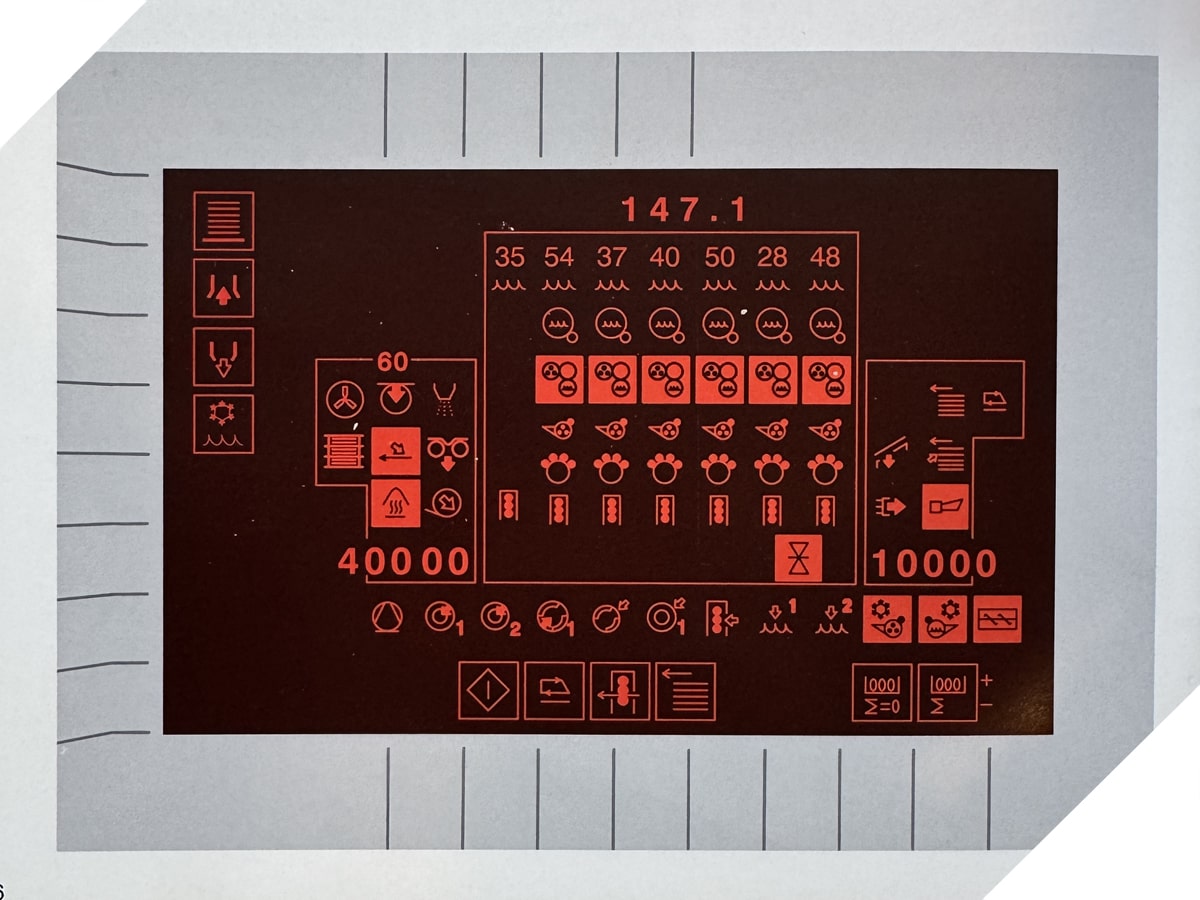

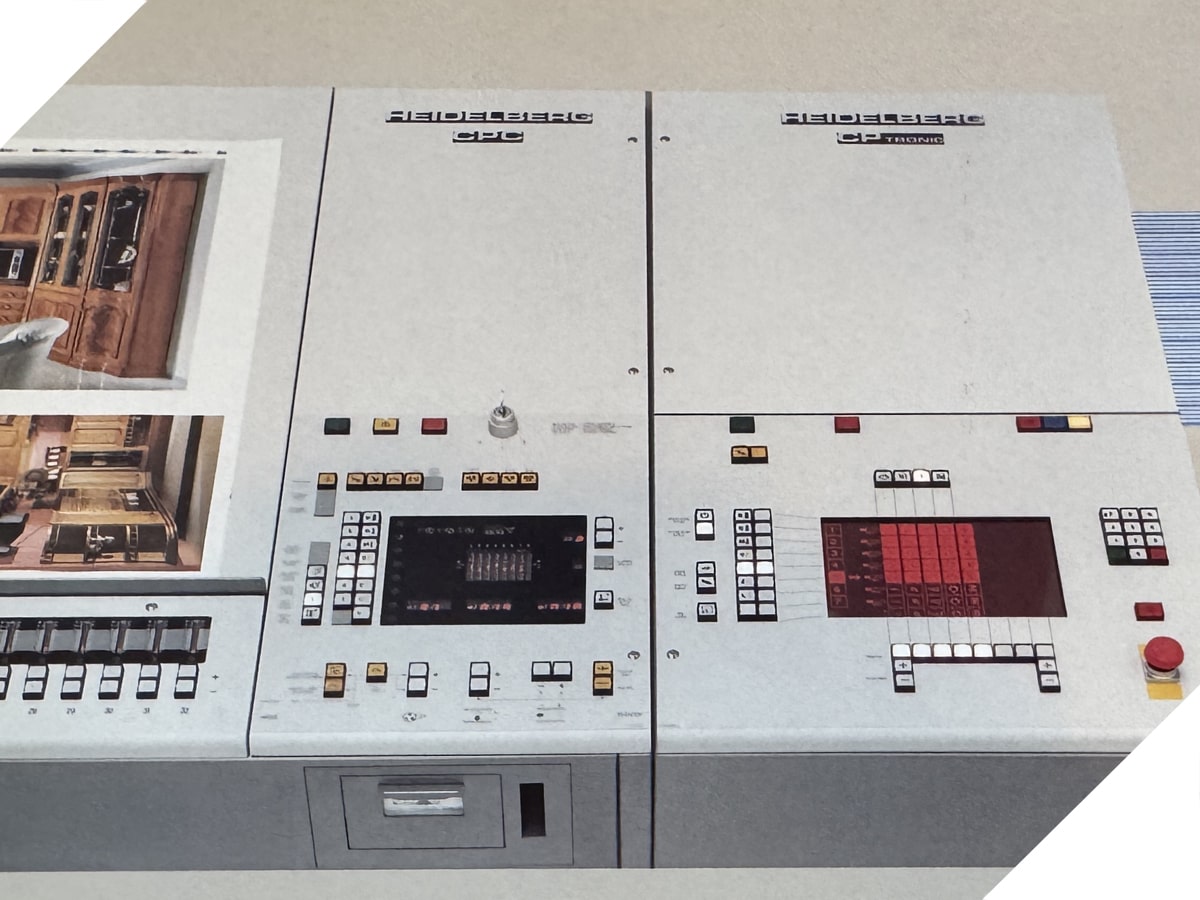

In the world of printing, the 1980s was an era of transformation, when mechanics and manual labour began to give way to digital technology. One of the symbols of this revolution was the Heidelberg CPC (Central Printing Control) range of digital printing controls. These modules ushered in a new era of automation, offering solutions that radically simplified and accelerated the work of printers.

With the introduction of the first CPC models, the printing process became more predictable and controllable than ever before. The ability to set parameters for ink, moisturising and other critical processes via a digital interface has greatly improved consistency and print quality. But most importantly, these devices have become the bridge between man and machine, allowing prepress data to be integrated with actual print parameters for the first time.

This article will explain how CPC devices have evolved from version to version, what they have brought to the industry and how Heidelberg has moved closer to a fully automated print production with each step. Those rare photos that I managed to collect in advertising leaflets from forty years ago, let’s save them for history.

CPTronic

First of all, the CPTronic machine control system should be mentioned. For the first time in the world, an attempt was made to introduce smart algorithms for controlling the supply of dampening solution, ink and air into printing machines by means of characteristic curves depending on the printing speed. Many people confuse CPTronic with the CPC control panel. But they are completely different devices.

The CPTronic was used to set the printing plate and adjust the ink register. In short, the CPTronic is the brain and nervous system of the machine, connected to its various components by wires. In this way, the printing process became much more predictable. The machine operator was now able to adjust and correct basic parameters without leaving his desk.

As the CPTronic improved, more and more sensors were added to the machine to tell the system the status of a particular parameter. It was there that the characteristic curves of speed-dependent control of print parameters were recorded.

CPC 1

The CPTronic control panel was a freestanding console located to the right of the CPC control panel, which is why many people think of them as a single unit. But that’s a bit of a misnomer.

The CPC was a convenient console for controlling the printing machine – colour zones, plate drive – while the CPTronic was responsible for interfacing operator commands to the machine.

Depending on the configuration of the printing machine, there were many versions of the control panel.

With each new version, the CPCs became increasingly intelligent and integrated, gradually transforming Heidelberg printing machines from fully mechanical to high-tech systems with automation and minimal human intervention.

CPC 1-01

Year of introduction: 1980

The first digital control system for sheetfed printing machines. Main purpose was manual adjustment of colour zones using a simple digital interface. Did not involve integration with other processes.

CPC 1-02

Year of introduction: 1982

Introduction of characteristic curves dependent on printing speed. This improved the accuracy of ink and dampening control. The system remained localised, with no link to prepress processes.

CPC 1-03

Year of introduction: 1984

Added the ability to memorise settings for repeat jobs, which simplified debugging. Introduced the basic concept of data transfer via special cards that were used to set up colour zones, but this was a local system not linked to external standards.

CPC 1-04

Year of introduction: 1986

Introduced at Drupa 1986. This version introduced the ability to work with digital cards containing colour zone data that could be transferred from a prepress plate scanner (built into the CPC 3). This technology predated the CIP3 standards, but was a closed Heidelberg system.

The CIP3 (International Cooperation for Integration of Prepress, Press and Postpress) standard was created in 1995-1996. These clarifications show that the Heidelberg CPC 1-04 technologies were the prototype of today’s integrated systems, but without the standardisation that came later.

CPC 2

The main parameters of the printing process were assigned corresponding numbers. For example, CPC 2-C was responsible for the spectrophotometric control of the printing process. Heidelberg deliberately took a more complicated route, deciding to base the measurement not on the optical density of the ink, but by determining colour coordinates in the CIE Lab system, which are then converted into the adjustment parameters of the ink unit gates on all (!) ink units. Can you imagine?

Of course, the company has also thought about the fact that the colour ductor will eventually wear out on the colour knife. If you’ve ever walked up to an old printing machine, you’ve probably seen a scratched ductor cylinder. But not on Heidelberg machines.

The CPC colour box has been designed in such a way that neither the ductor nor the knife have direct contact. That is, there is nothing to wear out in this pair. For wear and tear, a replaceable white polyester film was designed to be changed along with the cleaning of the paint box. The design was so successful that it is still in use today without much change.

CPC 3

This part was responsible for transferring data from the prepress process to the machine in order to reduce set-up time. In 1986, there was no CIP3 standard yet, or even a link to the plate process. Let me remind you that the plates were made from photographic films in a copy frame, and it was all done manually. It was worth changing the film developing temperature slightly, as the raster dot would increase. There was a concept of ‘veil area’ for photographic materials that changed with changes in developer temperature, exposure time, and development time.

Those who caught on to analogue photography can still remember how difficult it was to get the gradient right. When making a plate, the same factors occurred. You can imagine how much the printing process in those years depended on the skills of people in different professions. It was logical to set up the printing process not by the photographic film, but by the end result of the printing plate making process – after developing and processing.

This is what the very first system of scanning printing plates looked like.

In the second half of the 90s, the device changed its appearance and became vertical. The data was recorded on a special magnetic card that could contain setup data for up to 50 orders. The latest versions – CPC 31 even had the option of attaching the CPC 32 online to a printing machine for direct transfer of scanned data to the machine.

CPC 32 – Prepress Interface

So the CPC 31 was a plate scanner. Before printing, the operator scanned each plate, recorded its data on a special CPC card, and then inserted it into the machine’s control panel. The press automatically adjusted the colour zones. This process was calibratable and reduced machine set-up time.

Later, in 1990 with the development of computers and photo typesetters came the CPC 32, Prepress Interface. It was created for the first digital printing machine, the GTO 52-4 DI, where plate making took place inside the machine. The plate scanner was produced for a while, and to avoid confusion with the electronic device, it was renamed CPC 31.

The first compatible Heidelberg system appeared with the CPC 32, which was integrated with the prepress process via the Prepress Interface (PPI). It was a PC-based computer workstation with a special interface for connecting a printing machine. Therefore, unfortunately, we do not have a photograph of this device.

CPC 4

Finally, the CPC 4 was designed for quick register setting. The first version looked like a small sized box that looked like a densitometer. It was located on the control panel of CPC 1 table. When the printer set the plates and made a proof, he would scan the side crosses with this device. Even the printing machine automatically did the colour matching within ten seconds. This was also a small revolution, because a printer with experience, doing the colour matching manually, could do it in about five minutes.

In 1995, an even more modern version of the CPC 42, the Heidelberg Autoregister, was introduced. After the last print unit, a scanning ruler was installed, which checked the register during printing. What was the most importantly, it controlled the registration throughout the printing process!

The scale replaced the usual crosses for checking alignment, and took up only 5 mm on each side of the printed sheet.

CPC 5

In the second half of the 90s, CPC 5 was also presented, which referred to the production management system. The company’s management could control the machine load, determine the economic parameters of the output. But this system in those years was not yet so developed, so we will just mention it here. Complete solutions, which started from prepress processes and ended with postpress processes, began to appear a decade later, based on the JDF format.

The next phase of the CPC system upgrade came in 1996, a year after DRUPA.

Managing Director Hartmut Mehdorn acquired the Stahl-Brehmer plant in Leipzig, the Linotype-Hell plant in Kiel. At the same time, the Sheridan plant in the USA and even Harris, which produced rotary printing machines, became part of the Heidelberg Group. It became clear that the new system had to integrate all processes into one production management system. The old system could not cope with the new requirements and needed a major upgrade.

A couple of years later, Heidelberg became one of the founding members of the CIP3 data transfer format. As a result, all equipment will be able to ‘understand’ each other. Only then is it possible to integrate the entire printing process into a single production management system.

New generation

And in 1999, Heidelberg introduced its famous CP2000 touchscreen control panel to the market. This was not just a machine control device. It was a full-fledged computer with a spare parts catalogue, operating instructions and, most importantly, a user-friendly interface. Something similar in terms of functionality had only begun to appear in the competitors by 2006.

In 2000 the era of CPC components was left behind. All elements of the system received a new name – Prinect. Heidelberg has thus gone even further in terms of print automation and has once again left all competitors behind.

We know everything about printing machines. If you are buying used equipment, don’t rely on your subjective feelings, but order our official report on its technical condition.

Today’s walk through the city of Heidelberg will be a bit personal and even nostalgic. No doubt, after many years of working at Heidelberger Druckmaschinen, my heart has also stayed forever in this city, as sung in a famous local song.

I visited this beautiful city for the first time in the summer of 1998. These days, I was among dozens of new employees that Heidelberger Druckmaschinen had recruited to set up new branches and representative offices in various CIS countries. There is no doubt that we were the first, and I am proud that we were able to do so much to promote new modern technologies at the beginning of the 21th century.

This is us in July 1997: Sergey Chefranov (St. Petersburg), Dmitry Ermakov (Ekaterinburg), Sergiusz Woropaj (Minsk, Belarus), Rinat Adiatullin (Kazan), Oleg Lovkachev (St. Petersburg), Zulfiya Mashanlo (Aliati, Kazakhstan), Bakhtier Dzhanzakov (Tashkent, Uzbekistan), Andrey Kurusov (Rostov-on-Don).

Since then, we have brought clients here many times, come here for training. The city was changing before my eyes. I can’t escape the feeling that I have lived in Heidelberg for a significant part of my life. There is definitely something about this city that keeps me coming back.

It’s been a long time, but everything about Heidelberg and the city of romanticism is still a big part of my life. Whether it’s while checking out printing equipment, or just when I’m driving by, I make sure to stop by this city for a couple of hours to once again feel its charm. Today we can walk through familiar places to see how the city has changed and how we ourselves have changed.

Let’s start with the small and cosy train station. In the central square, just like 25 years ago, there is a huge bike car park. There is no McDonald’s anymore, but the Ibis Hotel, which used to house the service staff, is still there.

Inside the station, everything is still as we remember it. The well known bas-relief on the wall is still in its old place, and it even appears to have been restored.

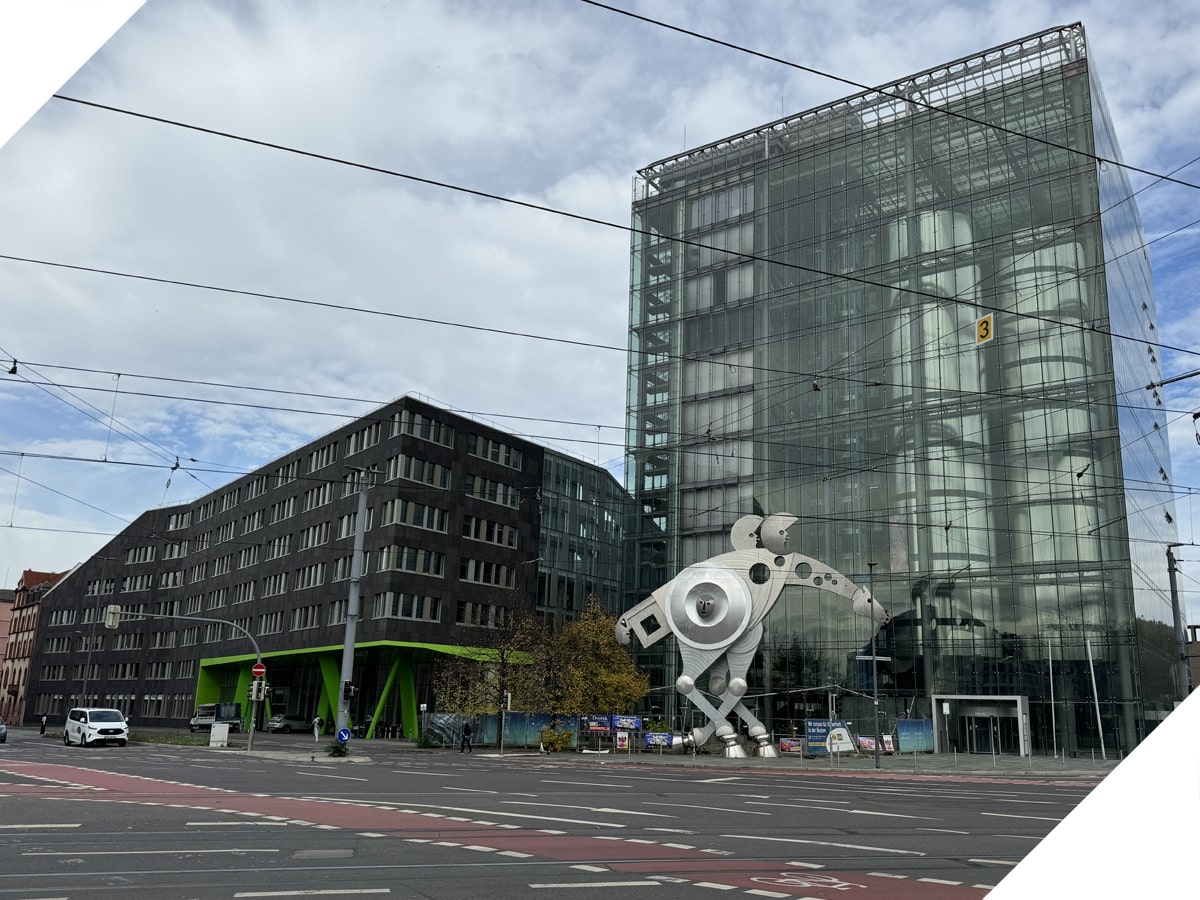

The Print Media Academy building located at the address Heidelberg, Kurfürsten-Anlage 52-60 was beyond the means of Heidelberger Druckmaschinen AG. Probably every visitor to the headquarters in the early 2000s has in his collection his own photo at the horseshoe of a printing horse with three legs.

The 50 metre high building was built between 1998 and 2000. It served for company training and events and was inaugurated by Federal Chancellor Gerhard Schröder on 14 April 2000. It has an area of 37 by 37 metres and cost almost 80 million German marks to build. In the front courtyard of the building stands the S-Printing Horse, one of the largest horse sculptures in the world, by Jürgen Goertz.

In 2020, Heidelberger Druckmaschinen withdrew its last employees from the city of Heidelberg. As a result, no more company employees worked at the Print Media Academy after the withdrawal from the city. In February 2021, Heidelberger Druckmaschinen announced the re-sale of PMA to an unspecified Luxembourg investment company. Nevertheless, until now, the building shows no signs of life…

The design of the building meant that it would be surrounded by a water track around its perimeter to symbolise the dampening process of offset printing. As you can see, the river has dried.

And inside the lobby you can see a huge drop of paint, inside which is a conference room.

The Academy of Print Media had 26 seminar rooms and an auditorium for 200 people, which could be rented for events and congresses. On floors 6 to 10 were offices. The last floor, the 12th floor, was home to the Schwarz restaurant from 2003 to 2014. After that, ‘Level 12’, an event space, was added there. As you can see, the old signs are still in place.

Right behind the PMA building, on the site of an old letterpress printing machine factory, are a residential neighbourhood with underground garages.

The building of the demonstration centre, which was built in the late 70s and early 80s, after the production of the machines was moved to Wiesloch, is now also closed. These walls still remember Hubert Sternberg and other famous company executives who once set the direction of the entire printing industry. Every visitor to the demo hall remembers this view.

The cement foundations for the demonstration printing machines can be seen on the floor, and the floor itself was an oak parquet in the form of cubes. It was extremely difficult to damage and so the parquet lasted longer than the demo hall itself. It wasn’t hard for me to walk over and take a few shots through the time-dusty glass.

I have a photo in my collection from the late 90’s when the letterpress crucible machine was still installed against the white wall.

Here’s another angle, we’ll save it for history. To this day, the architecture of the 70s is impressive and doesn’t seem outdated.

And this photo was taken at the place where many years ago all commemorative photos were taken of all visitors to the company’s headquarters. In my collection alone there are at least a dozen photos with my wonderful customers. The flags of the countries from which visitors were received were always displayed. They were updated daily.

Well, the spirit of the company still remains in the city, despite the fact that not a single employee actually works there anymore. Let us now walk through the streets of the old town and notice the pleasant little things that were once part of the visit for our visitors.

Life in the city of Heidelberg changed significantly almost instantly in the first part of the 2010s. The relocation of the US military headquarters from Heidelberg and the departure of Heidelberger Druckmaschinen AG led to a decent drop in property values. But, as the saying goes, ‘no place is empty’. The old students of the University community and the ubiquitous American soldiers have been replaced by a new crowd. The Heidelberg University with its infrastructure is still prestigious and popular. New buildings are being built in place of the old offices, and life seems to go on.

The Crown Plaza Hotel, where we used to accommodate visitors to the headquarters, is now occupied by a Hilton hotel. The last time I stayed at the Crowne Plaza was in the summer of 2021 during the easing of the bans after the coronavirus. I remember how at breakfast every bun, every cheese plate was sealed in transparent film. But the legend is gone. And how many funny stories about visitors this hotel remembers – can’t be counted. Maxim Rumyantsev, the general director of the Lubavitch printing house, wrote a whole book about them.

Bismarckplatz, familiar to anyone who has walked along the city’s longest street, Hauptstrasse. Unfortunately, the seven-storey department store Galeria Kaufhof on the square has been closed for many years. Apparently, its fate is still undecided, as well as what to do with the Heidelberger Druckmaschinen headquarters building. But you can find interesting photos on the fence erected around it. It turns out that the building was built in the late 50s as a Horten department store. Then it housed the Karstadt shop for a while, and then the well known Galeria Kaufhof opened.

Two photos taken from roughly the same angle. The photos were taken 63 years apart.

And this is what the square looked like in 1961

Even the pedestrian street changes. Some shops close, others open. My feeling is that the Hauptstrasse shops have become less sophisticated in recent years, and even the famous Kraus clothing shop, which for many decades maintained its independence and was a local landmark of the town, seems to have surrendered to mass merchandise. Only the monkey on the bridge remains at the same spot by the bridge over the Neckar, which is familiar to every visitor to the city.

But in spite of everything, the thing that has attracted people to Heidelberg since Goethe’s time remains a constant in the city – the romantic Elector’s Castle. The ruined castle reminds people that time passes and nothing lasts forever under the moon. The 175-year history of Heidelberger Druckmaschinen AG is also a clear proof of this.

And lastly, here we go again, more than a quarter of a century ago. Our friend Timur Rakhimov (Tashkent, Uzbekistan) joined us here. I know exactly the place where this picture was taken. It’s a restaurant right by the Alte Brucke Bridge, at Ob. Neckarstrasse 1.

That’s all for today, I hope you enjoyed it. And we are still available to help you inspect your printing machine if you have made the decision to purchase one. Order our detailed inspection before you pay money to the supplier for the equipment.

Don’t forget to subscribe to the newsletter on the main page. So you don’t miss out on new articles and special offers that will only be posted there.

Few people today remember who produced the first industrial printing machine that could do away with the long manual process of making printing plates. In the meantime, it was also the good old Heidelberger Druckmaschinen with its legendary model GTO. Today we will look back at this curious configuration, which became the forefather of today’s digital machines.

Heidelberg GTO (1972-2014). Part 1. A Printing Press From The Guinness Book of World Records.

Part 2. Prerequisites for the emergence of Computer-to-press technology

In 1990, the GTO printing machine base, proven for two decades, became the basis for another interesting configuration. Its appearance was predictable because of the imperfect plate process. The only question was when, by whom and how it would be realised. But first it is worth to tell about the prerequisites of its appearance.

The problem of the printing plate

Since the very appearance of offset printing, the most problematic and unpredictable issue has been the question of making printing plates. For decades, the process remained the same: first exposing the film, then exposing the plate. Only the technology has differed.

In addition to plates with a copying layer based on ortonaphthaquinodiazide compounds, known to most users of offset printing, bimetallic, trimetallic plates, plates based on larch gum, and even plates based on silver-containing compounds were developed for newspaper printing. But they all had the same flaws.

The problem of the copy layer of the plate

Why was the analogue process so unpredictable? In each of the intermediate preparation processes, the influence of human error was added. With photographic film, as with the plate, the reaction of the copy layer varied depending on the exposure, development, and the operator skills, of course.

If the film was slightly overexposed or underexposed, it immediately affected the size of the raster dot. If the developer temperature was changed, the veil area also changed. The operator, who exposed the plate, received a photographic film with an unpredictable result. In addition, the printing process itself depended on the skills of the operator.

That’s why many companies have been racking their brains on how to reduce the time it takes to make a plate, and more importantly, how to standardise it.

So, in 1990, on the basis of the long-suffering GTO printing machine, Heidelberg, in cooperation with the American company Presstek, demonstrated the FIRST truly DIGITAL PRINTING MACHINE IN THE WORLD. It was Heidelberg GTO 52 DI.

Appearance of a new star

Externally, the new machine did not differ much from the usual GTO. But inside it was very interesting. As in the case of the basic prototype, the new model could be equipped with both numbering and a perfecting device. It was available in four- and five-colour versions. Each print unit had its own laser head that exposed the printing plate.

Externally, the new machine did not differ much from the usual GTO. But inside it was very interesting. As in the case of the basic prototype, the new model could be equipped with both numbering and a perfecting device. It was available in four- and five-colour versions. Each print unit had its own laser head that exposed the printing plate.

There was no dampening unit in the machine, as Presstek had developed aluminium-based waterless offset plates specifically for this machine.

In addition, each of the machine’s ink units was thermostatically controlled. Maintaining a temperature of 25 degrees Celsius during printing was a necessity for these waterless plates. And the preparation of the single bit file for the laser head was handled by Linotype-Hell’s Delta RIP.

The print quality was excellent. This is confirmed by those rare impressions made on GTO DI lying on my desk right now. The quality was as good as standard offset process, but much more predictable. It had a short print life of about 10-15 thousand impressions, but it was sufficient for short runs.

A truly revolutionary solution was the possibility to apply the technology of making the printing plate inside the machine. It was done for the first time in the world in an offset printing machine.

In this way, Heidelberg eliminated potential errors at the prepress level.

The problems of the analogue plate making process were eliminated.

The printing process could be easily calibrated in full.

But the most important, the time to produce an offset print was reduced from a day to an hour.

Disadvantages of the new technology

The speed of 12,000 sheets per hour was excellent for accidental printing at the time. Yes, the printer removed and inserted the plate by hand. Yes, special waterless offset inks were required, which were twice as expensive as conventional inks. And the plate itself was not cheap, three times more expensive than a standard one. It was assumed that due to the increased urgency of order fulfilment the printing house would sell the products at a higher price.

But the most serious problem was the price of the machine. In fact, the print shop was buying 4x or even 5x exposing devices together with a conventional printing machine.

What else? Additional accessories that could be used online – such as numbering, imprinting, creasing and sheet cutting with the numbering shaft drive – have not been automated, and negated all the advantages of the new technology.

Heidelberg quickly realised the disadvantages of the new machine, but was not about to give up on the Computer-to-press technology that had been developed.

Subsequent development of computer-to-press technology

The GTO-DI machine was taken out of production in 1995. Instead, two models were launched on the market.

The GTO-DI machine was taken out of production in 1995. Instead, two models were launched on the market.

– Quickmaster QM46-4 DI with the Presstek waterless offset printing plates, but based on polyester (the moulds were rolled up). The same technology of dry offset.

– Speedmaster SM74 DI, which could be ordered in four-, five-, and even six-colour versions, with a varnishing unit. Each unit had its own exposure unit. Thus, the machine could handle both regular plates and waterless offset plates. Over time, when Presstek went bankrupt, the owner began to remove the exposure units and work on conventional plates.

The offset Computer-to-press technology was phased out due to the active development of modern Computer-to-Plate technology. Presstek still tried to sell its plates for some time. This is how Ryobi 3304 DI and Presstek 52 DI appeared, which was also produced under the Dainippon Screen logo. But the capabilities of the polyester-based moulding material were severely limited, and in the first half of the 2010s, Computer-to-press technology was modified.

Today its heirs are digital printing machines from HP, Canon, Konica Minolta, Xerox, Orient, Kodak, Landa, and many more, which have applied fundamentally different approaches to exposure inside the printing machine itself. But the pioneer was the Heidelberg GTO 52 DI machine, to which we must pay tribute.

We invite you to take a look at the video to see what this machine looked like in operation.

Used pictures:

Linotext, Cupertino CA, USA

Open sources

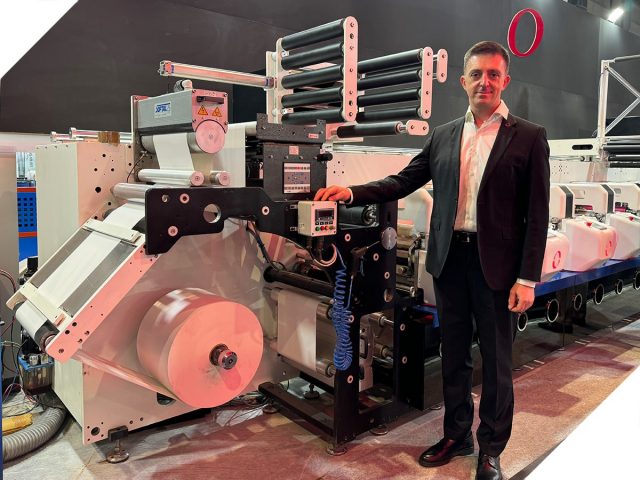

Hello to all subscribers from LabelExpo India! If by chance you happen to be at this show in Delhi, I will be happy to meet you on the 15th of November at the TPH Orient booth.

I would like to share what I have seen in this wonderful, colourful and unusual country. We will talk more about Heidelberg and Manroland later, but today I would like to share the impression I got when I visited the booth of TPH ORIENT India.

Can you trust Indian quality?

You can read the history of the company without me on the company’s website. But I want to tell you about what I saw with my own eyes during my visit to the exhibition. The products of this company have quite a long history. It was founded by a newspaperman and Indian freedom fighter, Mr K.D. Kohli, and has undergone quite an evolution in its life, which I would like to tell you about.

One of the visitors, a flexo technologist with vast experience from one of the CIS countries, after seeing the machine said literally: ‘This is probably the best flexo machine at the whole exhibition’. I thought so too, and I will try to demonstrate why it is so.

One of the visitors, a flexo technologist with vast experience from one of the CIS countries, after seeing the machine said literally: ‘This is probably the best flexo machine at the whole exhibition’. I thought so too, and I will try to demonstrate why it is so.

For many printers who have worked with German, Italian, British-made printing equipment, the word ‘Indian equipment’ evokes a wry chuckle. Sheet offset printers will remember licensed Dominants, web printers – machines Zirkon and RO-62 under licence from LBW Polygraph from GDR. But I want to assure you that this time is long over. Today Indian machines are not inferior to the best world models neither in price, nor in quality, nor in components.

The most famous products of TPH Orient are, of course, newspaper printing machines. If even your print shop did not have such a newspaper machine, you must have met them at exhibitions – from DRUPA to PolygraphInter. In the last 15 years, however, newspaper production has noticeably declined. The company has not lost its potential at all, on the contrary, it has managed to adapt perfectly to the changed conditions.

Today the production is based on digital narrow web machines and flexo lines. For assembly production mainly components of European companies with branches in India are used.

X-PRESS flexo printing machine

Let us walk the length of the flexo machine installed at the exhibition and try to pay attention to its features.

What immediately catches the eye is the impressive design with a red illuminated oval that contrasts with the dark blue and black colour scheme. The machine is without a doubt eye-catching and even mesmerising. I can say that the design is more oriented more towards European taste rather than Asian taste. The firm is constantly working on the design, so if you decide to order this machine, perhaps it will look even more interesting.

Overall impression

The machine is not simple and not primitive at all. It is based on the most modern servo drive. This reduces vibration, improves print quality by eliminating the run-out of gears. It is a pity that I forgot my vibrometer at home, which we use for equipment inspections. But even without it it is noticeable that the machine is quiet and stable at 200 metres per minute.

Please note that all components are assembled using European components, which are available locally. The systems responsible for web tension control, for coronary sensing of the material, for dust removal and for register control are made by the German company Erhardt+Leimer (EL).

Print unit

You can see for yourself how convenient it is to access the print unit. Ink can be added without stopping the machine from the left side of the machine. By opening the lid from above, the platemaking cylinder is accessible. Both conventional photopolymer moulds and sleeves can be used. The diameters of the cylinders can of course also be used.

You can see for yourself how convenient it is to access the print unit. Ink can be added without stopping the machine from the left side of the machine. By opening the lid from above, the platemaking cylinder is accessible. Both conventional photopolymer moulds and sleeves can be used. The diameters of the cylinders can of course also be used.

Longitudinal registering is carried out automatically by shifting the pinion along the paper web movement. Transverse register shifts the two cylinders in a horizontal plane.

Proprietary print unit. Orient’s patented X-gear design and gearbox integration system results in a Pitch Circle Diameter (PCD) of only 2 microns, resulting in a significantly faster machine, minimal noise at high speed, excellent register and higher print quality.

After the ink has been applied, UV drying comes into play. In this case, water-cooled GEW modules with 160 W/cm lamp power are installed. A refrigerator is installed behind the machine.

Peripherals

Above the machine is a mobile delamination-laminating system, a web turner, two units of rotary punching and a de-skimming unit.

Note the register control system. It is specially displayed on a huge monitor. The control module is manufactured by Erhardt+Leimer (EL).

Almost any equipment can be ordered as an option. Literally I was discussing the configuration of machines for convex braille.

So, why is this machine worth buying?

1. The company doesn’t skimp on the little things. If there is a 50 euro difference in the cost of a component, there is no point in compromising quality.

2- Higher quality purchased metal than most manufacturers. The steel casting suppliers are still the same as thirty years ago, from the days of coil machines.

3. Patented gear design. High PCD accuracy down to 2 µm, resulting in stable printing and quiet machine operation.

4. Possibility to use both photopolymer moulds and sleeves.

5. The most important thing – quick reaction in case of need of customer support.

If you choose a new flexo machine capable of printing stably at high speed, but at the same time for reasonable money, pay attention to this series.

The machines are supplied by BBS Trading. Here’s a link to their website.

Download the brochure for this machine here

And if you are choosing used equipment but would like to check its condition before paying the supplier, choose PressInspection’s services.

See you next time soon!

In some remote printing houses, you can still find silver-blue-coloured gatherers and folding machines with the logo of the manufacturing plant – LBW Polygraph.

What kind of manufacturer is this? Many young printers no longer know what this company is. But only a third of a century ago, both large printing plants and small reprographic sites throughout Eastern Europe were equipped mainly only with this equipment.

The history of this enterprise shows how unstable the socialist planned economy was. Large companies in East Germany, which had employed tens of thousands of people in the 1980s, were suddenly no longer needed, and the company’s divisions were privatised and resold to successful machine manufacturers in West Germany.

The old models of equipment from the socialist times were not characterised by high reliability. They were no longer of interest to the market in the 90s. But something new always grows on the wreckage of the old. What? Let’s find out.

How the printing industry was organised in the socialist group countries

The Second World War seriously redrew the borders of Europe. As a result, Europe was divided into two camps. Many people are not aware of this fact that in the GDR, Czechoslovakia and the USSR itself the production of printing equipment was also very well developed.

The two worlds – Western and Eastern Europe – were actively competing with each other. The Communists strove hard to show the advantages of the socialist system. East Germany even had its own analogue of the DRUPA exhibition – the Leipzig Printing Exhibition, where new products intended for export were actively exhibited. And of course, the most promising pieces of equipment received state prizes.

Despite the closed borders, the enterprises looked for partners in countries that were loyal to socialism and co-operated with each other. For example, the Rybinsk plant ‘Polygraphmash’ in the USSR produced feeders for East German ‘Planeta’ sheet-fed printing machines. These feeders had the ‘TIPO’ logo.

Despite the closed borders, the enterprises looked for partners in countries that were loyal to socialism and co-operated with each other. For example, the Rybinsk plant ‘Polygraphmash’ in the USSR produced feeders for East German ‘Planeta’ sheet-fed printing machines. These feeders had the ‘TIPO’ logo.

In turn, in India, under the licence of the plants from the socialist countries, roll-fed and sheet-fed printing machines were produced. RO-62 and Indian ADAST Dominant 700 series machines are still in operation in different countries of the world. ‘Planeta’ printing machines were spread all over the world.

The main difference between engineering in the Eastern Bloc countries is that there was no private business. Where it did exist, as in Poland, it was very limited in its possibilities. That is why all the printing machines produced in these countries until the collapse of the Soviet Union were oriented either to state-owned factories or to research institutes where documentation had to be reproduced.

We could say that LBW Polygraph is the father of many modern printing and postpress machines. At one time I myself have been searching for information about the history of this plant for a long time. Today I am ready to share it with you.

Polygraph Verner Lamberz

In the socialist part of Germany, due to the introduction and gradual development of the socialist planned economy, large associations – Vereinigung Volkseigener Betriebe (VVB) – began to form in the Soviet occupation zone and then throughout the GDR.

The VVB combined several state-owned enterprises (VEBs) into one sector. However, during the founding years of the GDR, VVB structures were largely unsuccessful and inefficient for a number of reasons.

The VVB combined several state-owned enterprises (VEBs) into one sector. However, during the founding years of the GDR, VVB structures were largely unsuccessful and inefficient for a number of reasons.

After the reorganisation of one of the VVBs in 1970, the Polygraph Werner Lamberts Combine became one of the leading industrial combines in the GDR. The head office and management headquarters was located in Leipzig. In 1979 it was named in honour of the late SED Politburo member Werner Lambertz. The combine was directly subordinate to the Ministry of Tooling and Machining Equipment.

It comprised eight state-owned companies with more than 40 production units in the paper-processing machinery sector throughout the GDR. The total number of employees was about 16,000.

The parent company of the company was VEB Leipziger Buchbindereimaschinenwerke (LBW), formed in 1960 by the merger of the two companies. There are:

VEB Buchbindereimaschinenwerk Leipzig (formerly Karl Krause),

VEB Falz- und Heftmaschinenwerk Leipzig (formerly Gebrüder Brehmer).

This company was the main supplier of postpress equipment to Eastern Europe.

Other important companies were:

VEB Planeta Radebeul, which produced large format sheetfed offset printing machines,

VEB Plamag Plauen, a company that specialised in web printing machines

VEB Kama (carton machines) Dresden, well known until now for its unbreakable die cutters like famous TS-96 and folding-gluing lines,

VEB Druckmaschinenwerke Leipzig, another factory that produced letterpress equipment, flexographic printing machines, but is especially remembered for its Zircon roller machines.

In addition, the mill had a foreign trade company , Polygraph Export GmbH. It was located in Berlin and was responsible for the mill’s goods. The machines produced by the GDR were really not bad. According to Wikipedia, in the 1980s about 50% of shopping bags in the US were printed on Polygraph machines.

The fate of the company after the reunification of Germany

After reunification in 1990, the mill was dissolved and the individual companies privatised. The most important companies were taken over by West German industrial leaders. For example, the former main plant became the Leipzig site of Heidelberger Druckmaschinen AG until its final closure in May 2015, Plamag Maschinenbau Plauen was bought by MAN Roland Group and Planeta Radebeul became part of Koenig & Bauer AG Würzburg.

KAMA, which manufactures punching presses and folding and gluing lines, has miraculously remained afloat. It is doing quite well, and their equipment can compete with Chinese equipment in terms of cost even today.

This story is interesting to people, even those with very little knowledge of printing, for many reasons. It’s about how important it is in our world to get your message right. The ‘printing press on wheels’ is an example of a colourful and unusual way of communicating your product to your target audience.

Our story today is about a remarkable and unusual example of product presentation, which deserves to be included in the book of world marketing achievements. It is about how to bring a mountain to Muhammad in an unusual way, at a time when Muhammad himself cannot approach the mountain.

Hubert Sternberg again

We have already told you about the enormous contribution to the success of Schnellpressenfabrik Heidelberg AG by its renowned CEO Hubert H. A. Sternberg. This is a man whose importance to the printing industry is comparable to that of Akio Morita for ‘SONY’, Lee Iacocca for ‘Chrysler’ or Steven Jobs for ‘Apple Inc’.

We have already told you about the enormous contribution to the success of Schnellpressenfabrik Heidelberg AG by its renowned CEO Hubert H. A. Sternberg. This is a man whose importance to the printing industry is comparable to that of Akio Morita for ‘SONY’, Lee Iacocca for ‘Chrysler’ or Steven Jobs for ‘Apple Inc’.

Born in Potsdam, he served in World War I after high school and then studied business management at Rudolf Mosset’s publishing company in Berlin. In 1923, at the age of 26, he took a job with the Kahn Group, where he quickly rose to director. Early in 1926, Richard Kahn asked him to analyse the company’s division located in Heidelberg, to determine if and how the ‘Schnellpressenfabrik’ problem could be solved.

Sternberg went to Heidelberg, inspected the factory and agreed – provided that he was given full freedom of action, especially with regard to the production programme, and five per cent of the shares. Kahn agreed to both conditions. (This was later recounted by Lothar Hoog, who had worked for the company for 50 years as sales manager for crucible printing machines; he only retired in 1974).

So the 29-year-old Sternberg arrived at ‘Schnellpressenfabrik’ in Heidelberg and took a leading role in what was to be a turning point in the company’s development. And stayed there for half a century.

This man successfully led the company through the Great Depression, the National Socialist dictatorship, World War II, and of course, after it ended, during the revival of the German economy. He was the originator of the DRUPA exhibition.

Read Hubert Sternberg’s story if you missed it.

Innovative ideas in marketing and production

On 22 June 1926, immediately after joining the firm, Sternberg was appointed to the board of management. Other members of the board were Ernst Schwarzländer, who had served as an alternate board member since 1920 (he retired in 1960), Oskar Leroy, and Wilhelm Meyrer, who only served on the board until March 1927. The driving force among them was undoubtedly Sternberg. Using modern advertising methods, innovative production techniques and continuous product development, he brought the company to the top of the printing machine industry.

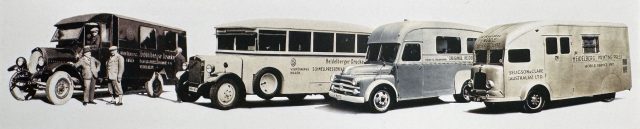

In the face of a global environmental crisis, the first priority was to stimulate business. Sternberg achieved this through new marketing and distribution methods. For example, he converted buses into demonstration machines transporting a fully operational Heidelberg crucible press-based printing press so that print shop owners and employees could watch the demonstration at their door. The demonstration buses were manned by mechanics who not only demonstrated the compact ‘print shop for everyone’, but also carried out necessary repairs or maintenance on other Heidelberg machines in the print shops while travelling around the regions.

In the face of a global environmental crisis, the first priority was to stimulate business. Sternberg achieved this through new marketing and distribution methods. For example, he converted buses into demonstration machines transporting a fully operational Heidelberg crucible press-based printing press so that print shop owners and employees could watch the demonstration at their door. The demonstration buses were manned by mechanics who not only demonstrated the compact ‘print shop for everyone’, but also carried out necessary repairs or maintenance on other Heidelberg machines in the print shops while travelling around the regions.

The ingenious system of financing the purchase from the company itself, was invented to facilitate financing for potential buyers. The factory itself provided instalments, while the customer’s financial situation was checked by a local agent. In this way, the customer did not have to deal with local financial organisations, which made it easier to obtain goods in countries just recovering from the First World War.

Many years later, such a system would also be applied in Eastern Europe, when the unstable financial system made it impossible to take out a loan for the purchase of equipment from a local bank.

Within a very short time, sales soared and production volumes did indeed have to be increased.

‘What was good for the ancestors was good for us.’

But at that point the independent sales and service companies responsible for selling Heidelberg printing machines had to get used to the idea. At first, they were unenthusiastic about such a strange sales and service policy. But soon their growing sales volumes enabled them to capitalise on this intensive customer service.

The former sceptics quickly turned into franchise distributors. Demonstration buses now travelled not only throughout Germany and Europe, but also to industrial centres in the USA, South America and India. Sternberg obliged all major ‘Schnellpressenpressefabrik’ agencies to purchase demonstration buses ‘in order to utilise this wonderful advertising tool in as many locations as possible to stimulate sales’.

After years of experience with these travelling demonstration buses, ‘Schnellpressenfabrik’ developed a standard version of the demonstration bus that was offered to agencies at half the regular price. In the mid-1930s, the company sold four of these ‘corporate image’ demonstration buses to France, two to the United Kingdom, and one each to Argentina, Brazil, India, South Africa, Australia, Portugal, the Netherlands, and Switzerland. By 1937, a total of 25 buses had travelled the world.

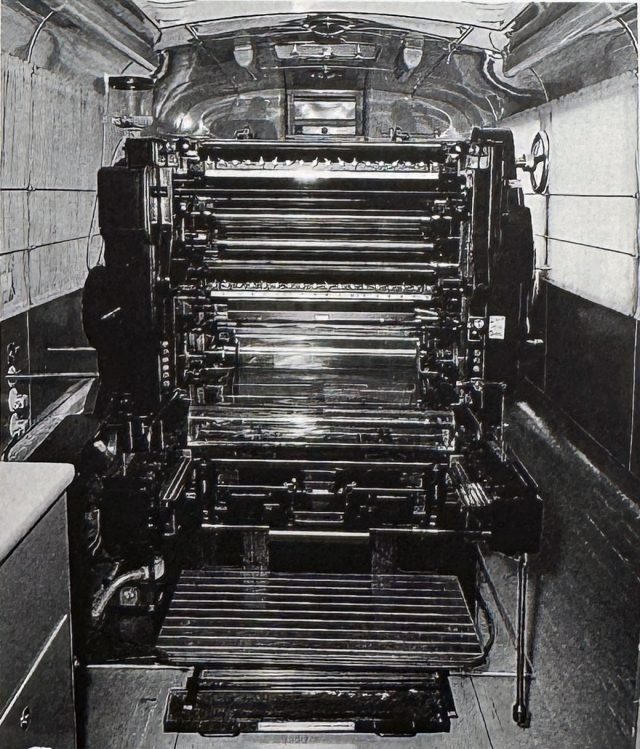

It should be noted that not only compact crucible printing machines, but even flatbed stop-cylinder presses were demonstrated on the buses. Here is a rare photo of what the saloon looked like with a KSB-type machine.

With his advertising acumen, Sternberg also saw an opportunity to strengthen his brand. He knew exactly how to make full use of the reputation of the place of production. After all, the whole world knew the romantic city of Heidelberg, sung in poems and songs by Goethe, Hölderlin, Keller and Viktor von Scheffel. So Sternberg named the printing machine ‘Heidelberger Tiegel’ (‘HeidelbergPlaten’), thus breathing life and romance into each of these seemingly soulless cast-iron machines.

The first machine is sold by the salesman, the second by the service engineer